Elanimal CNC Mill

It all started somewhere summer 2007. I always was intrigued by machine automation and had some ideas to build my own CNC milling machine.

But soon after I discovered that the money involved what too much for my budget. Yes, you can build a CNC machine with a limited budget but that will not result in a quality machine I'd like. When talking to Hans, owner of Elan Recumbents, Hans was willing to put up the money (and specifications) for a large CNC milling machine for milling some parts and molds for his "speedbikes".

It took 3 months to learn how to use a CAD program (Solid Edge) and to draw the complete machine. Meanwhile parts and materials have been bought and finally we brought the large aluminum plates to a local company for waterjet cutting.

Design

The original design was done in Solid Edge, using an educational license. I am now redrawing parts in SolidWorks to be able to make some modifications to some parts of the machine but also to update the drawings to the current changes that are not yet available in the older CAD designs.

This is a nice point in time to add some documentation on construction details.

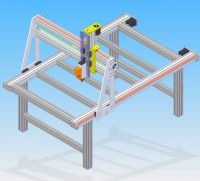

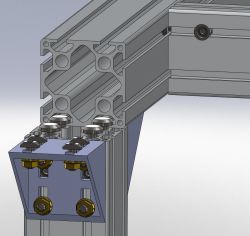

Attached picture shows how the frame is bolted together: the legs are mounted to the long profiles along the X-axis with 4 universal connectors and two angle connection sets per leg.

The universal connectors consist of an anchor and a cross bushing. By tightening the hex-screw in the bushing the anchor is fixed, creating a very stable connection. The angle sets are used to provide some extra stability and to prevent the whole table to shake while the X-axis moves.

The bars in between both front and rear profiles only use universal connectors. The 15mm aluminum sheet that is screwed on top of the profiles provides for a rigid construction.

Assembling all parts

This was the most exiting part of the building process.

The parts from the waterjet arrived just before christmas, the aluminum profiles (MayTec heavy duty profiles for machine building) and all the nuts & bolts have been delivered also. Now it's almost a Meccano set, just a big heavier.

After 3 days I'm ready to fire up the machine for the first time.